|

Optimization & Rebuilds

From a simple repair to a full on rebuild we have the background and know-how to do the job. Our team works with you to identify the most cost effective solutions to achieve your project goals.

|

Tune-Ups

A tune-up to put your headbox back in optimal condition includes polishing the internals; zeroing macro and micro lip adjusters; optical alignment, honing & polishing of slice lip and apron.

|

TFE Coating

TFE (identical to Teflon™) coating the headbox internals and delivery surfaces prevents stock buildups that can dislodge, causing streaks, holes, sheet breaks, and wire damage.

|

|

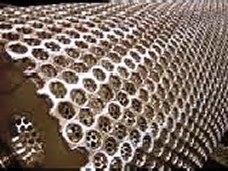

Rectifier Rolls

Spinnaker is one of the few North American sources for rectifier rolls.

|

Slice Lips, Profile Bars and Apron Lips

We provide new slice lips, profile bars, apron lips and apron blades in stainless steel and titanium, with or without TFE coating. We also refurbish existing lips, bars and blades.

|

Headbox Components

Cheek pieces; edge feeds; tube banks; attenuators; pond sides; seals; stationary showers; cladding; and custom designed components.

|